VHE Systems

Crucial sub-systems for every machine

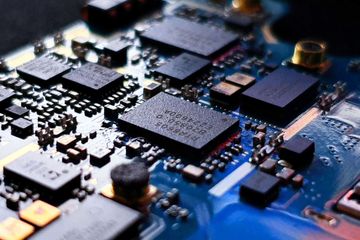

Machine Control

The Machine Control system is the 'nerve centre' of the high-tech machine

The most important function of the Machine Control system is to receive and process (sensor) data, and to drive the machine’s physical control system. We develop and assemble complex control cabinets, panels and PCB solutions, as well mechanical components such as plating, gutters and hoses. We are electro-specialists with a feel for mechanics.

Machine Connectivity

Machine Connectivity systems are the 'nerve centres' of a high-tech machine

Machine Connectivity systems are the ‘nerve centres’ of the high-tech machine. Their most important function is to transmit crucial signals, data and power from the Machine Control system to the components. We design, assemble and test complex cable sets and harnesses that are renowned for their excellent performance and reliability in very demanding settings.

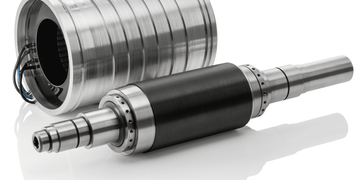

Motion Control

Motion Control systems move objects in one or more directions

It goes without saying that precision, high speed and reliability are essential in high-tech machines. We develop and dimension the complete Motion system, including the control software.

We are the certified motion partner of Bosch Rexroth, Lenze and Siemens.

VHE offers specific tailor-made solutions for motion control, in partnership with Georgii Kobold, GMN, SIEB & MEYER and SPN. We are the sole representation in the Benelux of these 4 high-tech companies in Motion Control.

Assembling your existing products and developing your next high-tech innovation for and with you; that is the strength of our people!- Peter Beerens, CTO VHE Industrial automation

Tested for 100% certainty

With the VHE Inline testing equipment for systems and complete machines, we guarantee a high First-Time-Right score, greater efficiency, and a shorter lead time. We have all the equipment and functionality for testing (also in our own cleanroom) and for simulating the process steps of the system.

You can always rely on us

Fulltime Employees

High-tech clients

Batch size

Years of experience

m2 in the Brainport region

Ask us to carry out a technology scan

Assembling your existing products and developing your next high-tech innovation for and with you; that is the strength of our people!

Machine Control

Machine Control

Machine Connectivity

Machine Connectivity

Motion Control

Motion Control