Cases

VHE in practice

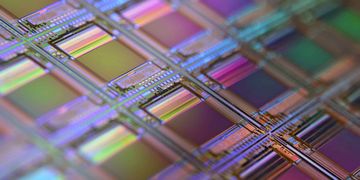

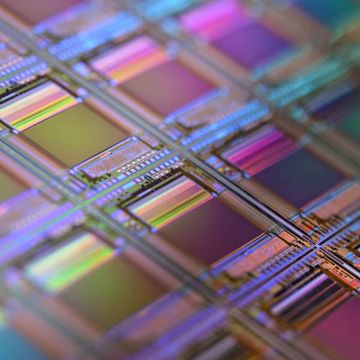

Semicon: The digitalisation of the world is unstoppable

VHE operates in the semicon, high-tech and smart energy market segments.

An explosive growth is currently taking place, especially in the semicon market segment, because the world is continuing to digitalise. The number of chips in cars has quadrupled, and large quantities of chips are needed for our energy transition (solar panels, wind turbines, electricity networks). Furthermore, Europe is keen to (re)establish its own semiconductor industry.

Find out what we do in the semicon market

In this market segment, VHE works for globally renowned multinationals but also for promising start-ups. Machine Control, Machine Connectivity and Motion control are all applied, whereby work is often carried out in a cleanroom environment.

VHE is a long-term partner and extremely pro-active in carrying out our wishes. Furthermore, they have excellent in-depth knowledge of control systems and understand our machine inside out. As a result, we as an OEM can focus on our core technology.- Walter van de Pol, CEO Raith

Walter:

Raith is a leading supplier of solutions for electron beam lithography, FIB-nanofabrication, nano-engineering and reverse engineering. We have been working for years with VHE.

VHE was responsible for the engineering of the control cabinet and control modules of the machine as well as for all the cabling. They also helped us to develop part of the PLC.

VHE is also responsible for the production of the electrical control cabinet as well as various other integrated electrical modules, and all the cabling required for our machine. It is built from scratch in VHE’s cleanroom facility. This will include all the cabling and the control cabinet. On completion, the machine will undergo a functionality test in the cleanroom.

Regarding the engineering and production stages, we have frequent contact with VHE, which is necessary because VHE manages our design package. This means that changes can be discussed together and acted upon without delay.

A welcome plus is VHE’s self-developed quality and management system, “Zerox”. All relevant production and test data is stored on the system and can therefore be located quickly.

A significant advantage is that the people at VHE know our machine and ‘half a word is enough’. That’s what I call a fruitful partnership.

The art is not to avoid criticism but to be able to deal with it constructively. Afterall, you both want to achieve the same goal. VHE has always done really well in that respect.- Jan do Livramento, Supply Chain Director Nearfield Instruments

Jan:

Nearfield Instruments builds machines in the semicon world. We build metrology machines that measure the surface of chips at atom-scale resolution. Atomic Force Microscopy technology enables us to measure Van der Waals forces using an ultra tiny needle, which is not actually visible to the naked eye. The force is proportionally distributed around the atom and varies the closer the surface of the atom is approached.

The project:

A Nearfield machine is made up of various parts and many different suppliers are involved in building them. One of the essential parts is the Design and Serial production of the Machine Control system and the Machine Connectivity. VHE is specialised in building the structure into which all the electronics are placed, as well as all the corresponding cables. This is the cabinet with all interfaces as well as a couple of hundred cables through which hundreds of signals pass. And it’s built under cleanroom conditions.

The individual parts for the control cabinet come from dozens of different suppliers. So VHE has to make sure the coordination between those suppliers and Nearfield runs smoothly and efficiently in order to achieve a working end product.

Status:

We have been working with VHE since 2018. The biggest challenge we have had to face together since then was the engineering and construction of the first prototype, which had to be compact and yet still able to house so many different components. How can you continue to work well together with so many uncertainties? If a company succeeds under those circumstances, then it has proved that it can work together with a start-up (in the meantime, a scale-up). The technology was a challenge but what was more important was working closely together throughout. It’s not about shouting the loudest, it’s about achieving the most. And, what’s more, you’re both interested in achieving the same goal. VHE has always done well in that respect. You need people around you who believe in what they’re doing. And that is the case with VHE.

Finally:

VHE is transparent and open during our discussions together. They embrace new developments. They don’t withhold information even if they might be afraid that things could be misinterpreted. From the commercial point of view, they are also transparent, and I find that extremely valuable.

Hightech: Using technology for future solutions

VHE operates in the semicon, high-tech and smart energy market segments.

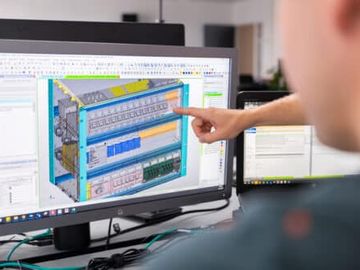

The high-tech industry is broad. It is an industry in which, with the help of new technologies, machines for the future are being developed. Examples are: 3D metal printing, robots in the agri-tech world, and ultra fast packing machines.

Find out what we do on the high-tech front

In this market segment, VHE works not only for globally renowned multinationals but also for promising start-ups. The most important criteria for us is that clients are technology leaders and on-going innovators in their sectors, and that Machine Control, Machine Connectivity and Motion Control are all applied.

VHE is an important partner for us. They have an excellent team of system architects, engineers and technicians who are working with us on our machine. Our teams work extremely well together due to mutual trust, openness, and efficiency.- Mark Vaes, CTO Additive Industries.

![]()

Mark:

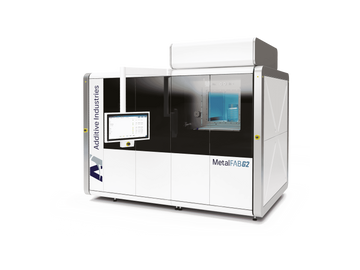

Additive Industries manufactures industrial 3D metal printers for high-quality metal parts. It offers a system specifically aimed at high-end and demanding industrial markets such as the aerospace and automotive sectors.

In 2014, Additive Industries selected a number of partners for the development and production of their first MetalFAB 3D printer. This whole traject had to be completed within the very ambitious time frame of 36 months. The chosen partners in the Brainport region committed to bringing this ambitious plan to a successful conclusion. According to plan, the result was a modular high-tech printer that conformed to all norms.

As one of our illustrious partners, VHE is responsible for the electrical concept, system architecture, prototype, and serial construction of the MetalFAB printer, as well as for the engineering and production of all its electrical panels. They also engineer and produce the high-tech cable set that links all components and modules; around 600 cables in total. VHE has also developed several test modules so that each individual module manufactured by Additive Industries or one of its suppliers can be tested in advance.

Cooperation within the Brainport region is at the core of our success. VHE works well with colleague-partners in the high-tech industry, which takes the burden off us as OEM. VHE’s business culture is one of openness, short lines of communication, acting without delay, and mutual trust. And that corresponds exactly with Additive Industries’ business culture.

Smart Energy: Climate change must be prevented at all costs

VHE operates in the semicon, high-tech and smart energy market segments.

Climate change must be prevented at all costs. The path towards a CO2-neutral world calls for a transition to CO2-neutral energy sources, which nearly always involves electricity networks. With its knowledge of electrical power, VHE can play an important role in the development and implementation of appropriate solutions to aid this transition.

Discover what we do in the smart energy market

In this market segment, VHE works with a variety of promising scale-ups. Machine Control and Machine Connectivity are applied, amongst other things, in high-energy batteries for buses and trucks, remote solar parks for supplying energy to factories, and decentralised energy buffers for the prevention of net congestion.

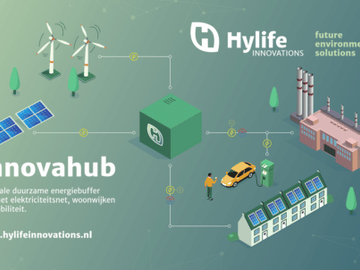

VHE is an excellent partner; they are creative and critical and have the courage to speak out. They also show genuine commitment.- Jean-Paul Scheurleer, CEO Hylife Innovations

Jean-Paul:

Energy transition: everyone is talking about it but there are only few who successfully complete actual projects. There are many who devise wonderful pilots and then conclude that realising their plans is a bridge too far. We work the other way round. The emphasis is on DOING. We have devised an energy system that we are currently implementing in neighbourhoods, which enables us to produce, buffer and smart-control emission-free energy. We call it the Innovahub. We are solving current problems such as net congestion, the gas issue, the climate crisis, and the housing crisis. A battery, hydrogen storage, solar cells / wind turbines, and smart software are all used in our energy system.

We came into contact with VHE via ABB. Both VHE and Hylife Innovations were having discussions with ABB on developments in the areas of energy transition, simulation software and energy control systems (ECS). Since then, VHE has developed our Energy Control System and is responsible for putting together the Innovahub. Machine Control, Machine Connectivity as well as mechanical aspects are all involved. So, from the very first Concept, via Design, through to Serial Production, we have worked closely together. Marc and Joop got on well because both believed in the importance of long-term vision. Reliability and the feeling of working with a family enterprise also played a part. We are operating in a whole new world full of uncertainties which means that we have to be able to work really well together.

VHE is the perfect partner to realise this pilot in an industrial environment. Working from a concept, they are able to architect and engineer what is necessary; they are creative and critical. And they have the courage to speak out. They radiate professionality and stick to the agreements made. And lastly, they show genuine commitment.

In total, we work closely together with 16 partners. They all take responsibility for their part in the project and are prepared to invest in this new world.

Semicon

Semicon

Hightech

Hightech

Smart Energy

Smart Energy